Scroll Air Compressor

Say goodbye to frequent maintenance, our advanced design dramatically reduces upkeep while delivering unmatched reliability, whisper-quiet operation, and exceptional energy efficiency. With frictionless, oil-free technology and an eco-friendly approach, RUEGO ensures clean, hassle-free performance tailored to your needs.

Completely Oil-free

Power

3.7 kW~30 kW | 5 HP ~ 40 HP

Exhaust Volume

0.36~3.2 m³/Min | 12.71~113.01 CFM

Exhaust Pressure

8~10 Bar | 116.03 PSI~145.04 PSI

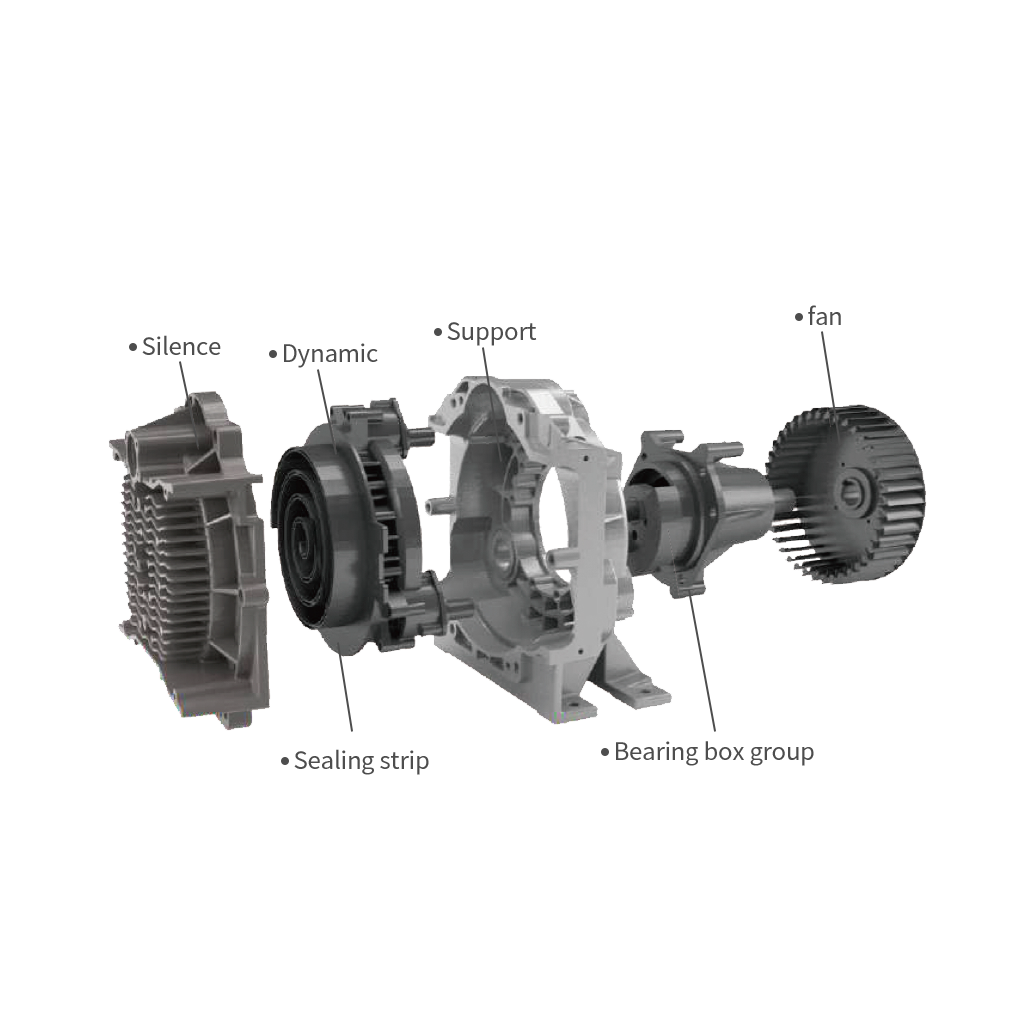

Innovative Oil-Free Scroll Main Engine Design

Made using precision aluminum alloy casting, this product ensures exceptional durability under high-temperature and high-pressure conditions. The innovative self-compensating sealing design provides outstanding sealing performance, minimizing maintenance frequency and extending service intervals. Combined with professional surface treatment, this design guarantees reliable and long-lasting performance.

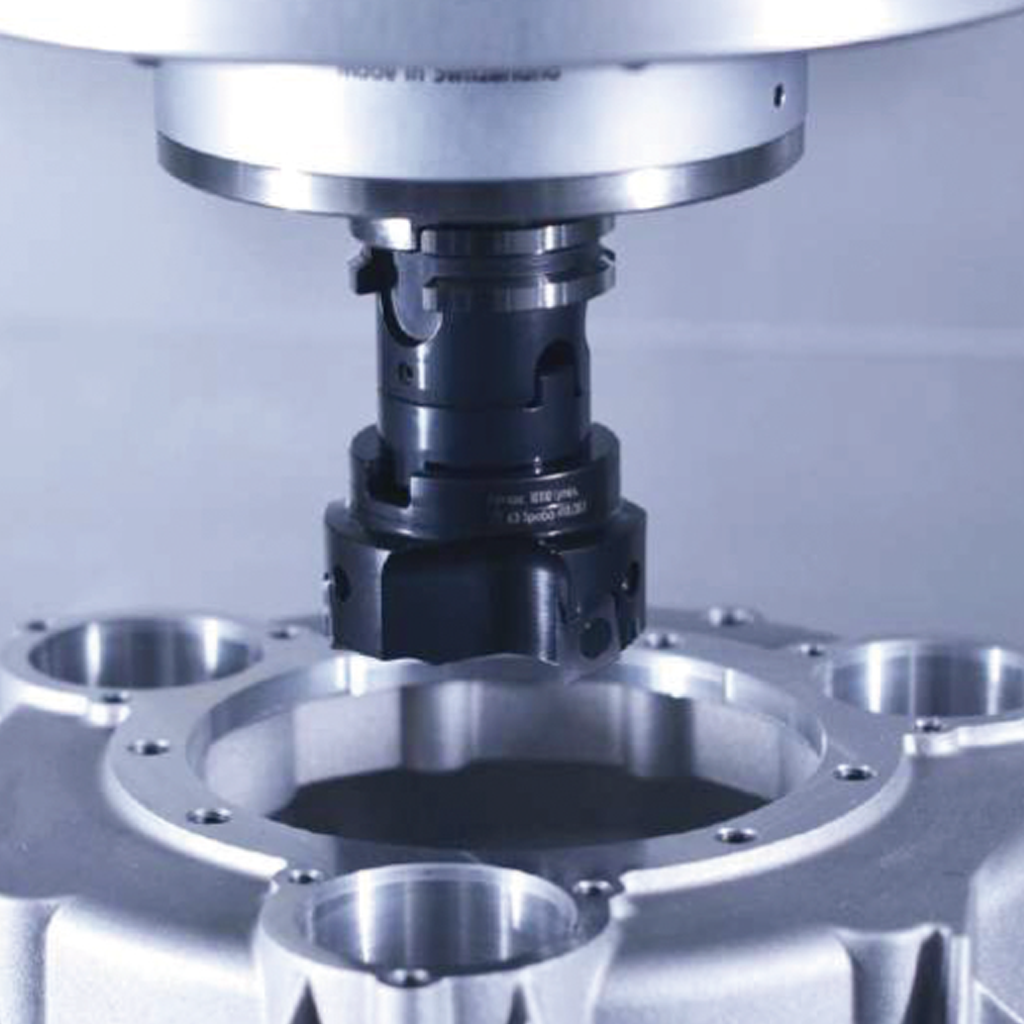

Precision Engineering for Unmatched Accuracy

Advanced casting technology combined with precision machining equipment ensures that core components achieve micron-level accuracy, delivering high performance. The groundbreaking system structure simplifies the design of traditional air compressors, reduces the number of parts, and improves efficiency. The perfectly meshed dual-curve compression eliminates mechanical friction, enabling lubrication-free operation and unparalleled durability.

Reliability and Sustainability Redefined

Reliable motion mode minimizes mechanical vibration, delivering continuous and stable exhaust while extending product life and reducing maintenance costs. With cutting-edge technology and meticulous engineering, our oil-free scroll air compressors provide sustainable, high-quality compressed air solutions.

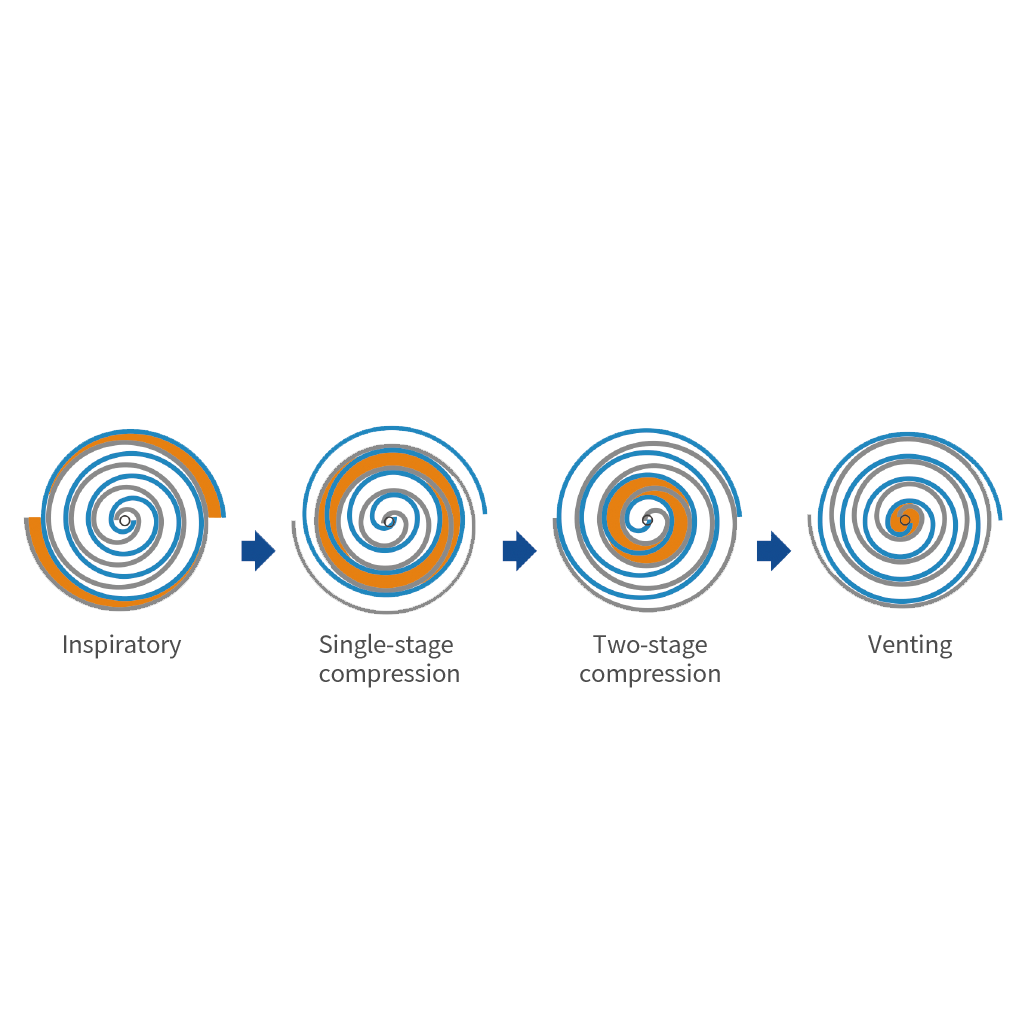

Working Principle of the Scroll Compressor

The working principle of the oil-free scroll air compressor involves the dynamic scroll disk rotating smoothly around the base circle center of the static scroll disk, following the sequence illustrated in the diagram on the left. During operation, air is drawn in through the intake port of the static scroll disk via an air filter.

As the dynamic and static scroll disks intermesh, crescent-shaped compression chambers are formed. With the continuous rotation of the dynamic scroll disk, these chambers progressively decrease in volume, compressing the air inside. This process ensures a steady flow of clean, oil-free, high-quality compressed air, which is discharged from the center of the scroll disk.

The entire operation is designed for stability and efficiency, with non-contact operation between the moving and static scroll disks. This frictionless design minimizes wear and extends the lifespan of all components, making the Oil-Free Scroll Air Compressor a reliable and durable solution for delivering high-performance compressed air.

Product Parameters

* For higher specifications please contact our sales team.

| Model: | OXW-5HPM |

| Power: | 3.7 kW / 5 HP |

| Voltage/Frequency: | 380V/50Hz (Customizable) |

| Driven Mode: | Belt drive |

| Noise: | 49±3 Db(A) |

| Air Outlet Pipe Diameter: | 3/8 |

| Gas tank capacity: | 24 L |

| Controller Type: | Pressure switch/Multi-line controller |

Air Pressure & Volume flow

| Air pressure | Volume flow | 6.5 bar~10 Bar | 0.36~0.4 m³/min |

|---|

Size & Weight

| Length*width*height | Weight |

|---|---|

| 700*650*1000 mm | 195 kg |

| Model: | OXW-10HPM |

| Power: | 7.5 kW / 10 HP |

| Voltage/Frequency: | 380V/50Hz (Customizable) |

| Driven Mode: | Belt drive |

| Noise: | 55±3 Db(A) |

| Air Outlet Pipe Diameter: | 3/4 |

| Controller Type: | Multi-line controller |

Air Pressure & Volume flow

| Air pressure | Volume flow | 6.5 bar~10 Bar | 0.72~0.8 m³/min |

|---|

Size & Weight

| Length*width*height | Weight |

|---|---|

| 930*630*1090 mm | 300 kg |

| Model: | OXW-15HPM |

| Power: | 11 kW / 15 HP |

| Voltage/Frequency: | 380V/50Hz (Customizable) |

| Driven Mode: | Belt drive |

| Noise: | 57±3 Db(A) |

| Air Outlet Pipe Diameter: | 3/4 |

| Controller Type: | Touch screen controller |

Air Pressure & Volume flow

| Air pressure | Volume flow | 6.5 bar~10 Bar | 1.08~1.2 m³/min |

|---|

Size & Weight

| Length*width*height | Weight |

|---|---|

| 1100*980*1440 mm | 460 kg |

| Model: | OXW-5HPM |

| Power: | 15 kW / 20 HP |

| Voltage/Frequency: | 380V/50Hz (Customizable) |

| Driven Mode: | Belt drive |

| Noise: | 59±3 Db(A) |

| Air Outlet Pipe Diameter: | 1” |

| Controller Type: | Touch screen controller |

Air Pressure & Volume flow

| Air pressure | Volume flow | 6.5 bar~10 Bar | 1.44~1.6 m³/min |

|---|

Size & Weight

| Length*width*height | Weight |

|---|---|

| 1100*980*1440 mm | 540 kg |

| Model: | OXW-25HPM |

| Power: | 18 kW / 25 HP |

| Voltage/Frequency: | 380V/50Hz (Customizable) |

| Driven Mode: | Belt drive |

| Noise: | 61±3 Db(A) |

| Air Outlet Pipe Diameter: | 11/2 |

| Controller Type: | Touch screen controller |

Air Pressure & Volume flow

| Air pressure | Volume flow | 6.5 bar~10 Bar | 1.8~2 m³/min |

|---|

Size & Weight

| Length*width*height | Weight |

|---|---|

| 1400*1000*1440 mm | 750 kg |

| Model: | OXW-30HPM |

| Power: | 22 kW / 30 HP |

| Voltage/Frequency: | 380V/50Hz (Customizable) |

| Driven Mode: | Belt drive |

| Noise: | 62±3 Db(A) |

| Air Outlet Pipe Diameter: | 11/2 |

| Controller Type: | Touch screen controller |

Air Pressure & Volume flow

| Air pressure | Volume flow | 6.5 bar~10 Bar | 2.16~2.4 m³/min |

|---|

Size & Weight

| Length*width*height | Weight |

|---|---|

| 1400*1000*1440 mm | 840 kg |

The Role of Scroll Air Compressors Across Different Sectors

Medical Industry: Ensuring Clean Air for Critical Applications

In the medical field, the purity of compressed air is essential for ensuring patient safety. Oil-free scroll air compressors provide a reliable source of clean, contaminant-free air for operating rooms, ventilators, and other critical medical equipment. Their quiet operation and vibration-free design make them ideal for sensitive healthcare environments. Additionally, their long service life and reduced maintenance requirements enable healthcare providers to focus on delivering quality care without worrying about air supply reliability. By eliminating the risk of oil contamination, these compressors ensure compliance with the strict hygiene standards of the medical industry.

Pharmaceutical Production: Ensuring Clean and Compliant Processes

Pharmaceutical manufacturing requires strict adherence to cleanliness and safety standards. Oil-free scroll air compressors provide the clean, contaminant-free air necessary for drug production, packaging, and material handling. Their innovative design minimizes the risk of contamination, ensuring compliance with Good Manufacturing Practice (GMP) standards. Additionally, their long-lasting, low-maintenance construction supports uninterrupted production, reducing downtime and increasing overall efficiency. These compressors are indispensable in maintaining the quality and safety of pharmaceutical products while optimizing operational performance.

Laboratories and Research Facilities: Delivering Reliable Performance

Research facilities and laboratories rely on compressed air for a variety of applications, including powering instruments like gas chromatographs and mass spectrometers. Oil-free scroll air compressors deliver ultra-clean, consistent air that meets the strict demands of scientific research. Their low noise levels and stable operation ensure an ideal working environment for researchers. With a design focused on durability and efficiency, these compressors reduce operational costs and support the accuracy and reliability of critical experiments, making them a trusted choice for advanced scientific applications.

Food and Beverage Processing: Guaranteeing Product Integrity

The food and beverage industry requires oil-free compressed air to prevent contamination during the production process. Oil-free scroll air compressors provide high-quality clean air, making them an ideal choice for packaging, mixing, and bottling processes. Their efficient and quiet operation helps maintain a safe and comfortable working environment while supporting compliance with strict food safety regulations, ensuring product purity and maintaining consumer trust in highly regulated industries.