Choosing the right air compressor can be a daunting task, especially when deciding between scroll compressors and rotary compressors. Each type has unique advantages and disadvantages, making them suitable for different applications. In this article, we will explore the working principles, features, and ideal industries for both compressors to help you make an informed decision.

Table of Contents

Working Principles and Features of Scroll Compressors

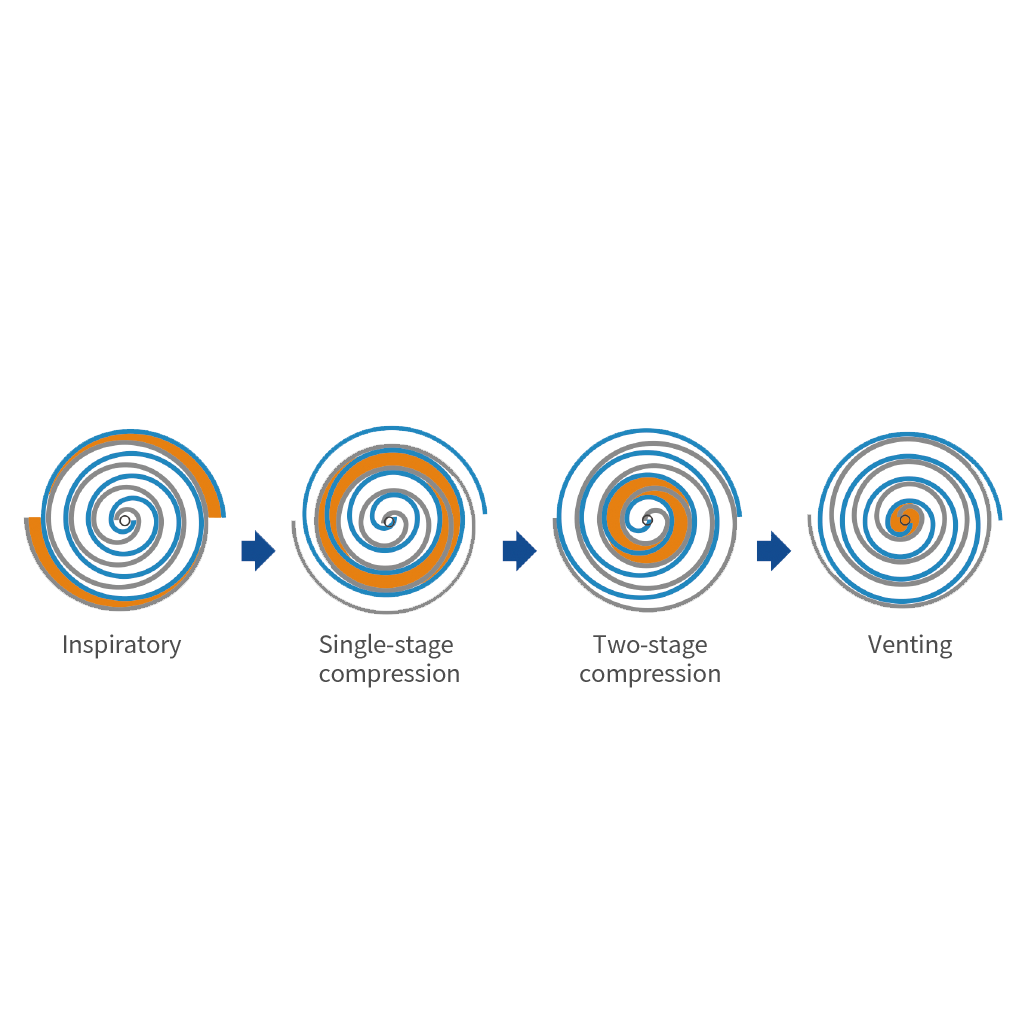

Working Principle

Scroll compressors operate by using two spiral-shaped scrolls. One scroll remains stationary while the other moves in a circular, orbiting motion. This motion traps and compresses gas within progressively smaller pockets formed between the scrolls.

Advantages

Energy Efficiency: Scroll compressors minimize internal leakage, ensuring high efficiency.

Quiet Operation: With fewer moving parts, scroll compressors produce very low noise, making them ideal for noise-sensitive environments.

Compact Design: They occupy minimal space, making them perfect for installations where space is limited.

Disadvantages

High Initial Cost: The complex manufacturing process results in a higher price tag.

Sensitivity to Contaminants: Requires efficient filtration to prevent damage from dirt or moisture.

Limited Capacity: Best suited for low to medium capacity applications.

Working Principles and Features of Rotary Compressors

Working Principle

Rotary compressor operate on the principle of positive displacement. They use two interlocking helical screws, also known as rotors, that rotate in opposite directions. As the rotors turn, air is drawn into the spaces between the screw threads. The rotational movement reduces the volume of these spaces, thereby compressing the air. This compressed air is then discharged through an outlet.

Advantages

Continuous Operation: Designed for long-term, uninterrupted use, making them ideal for industrial environments.

Ease of Maintenance: Fewer components reduce the likelihood of mechanical failure.

High Efficiency: Excels in high-demand applications.

Disadvantages

High Initial Cost: Advanced engineering contributes to a higher purchase price.

Generates Heat: Requires additional cooling systems for stable operation.

Specialized Maintenance: Requires skilled technicians for servicing due to complex systems.

Performance Comparison: Scroll Compressors vs Rotary Compressors

| Performance Metric | Scroll Compressors | Rotary Compressors |

|---|---|---|

| Efficiency | High for low-medium demand | Excellent for high demand |

| Noise Level | Ultra-quiet | Quiet but louder than scroll |

| Maintenance Cost | Low, periodic cleaning needed | Higher, requires expertise |

| Applications | Medical, labs, residential | Industrial, construction |

Best Applications for Each Compressor

Scroll Compressors

Medical Facilities: Ideal for hospitals and labs requiring quiet operation.

Residential HVAC Systems: Compact and silent, perfect for home use.

Small-Scale Manufacturing: Suitable for moderate air volume needs.

Rotary Compressors

Industrial Manufacturing: Suitable for automotive, heavy industry, and large-scale production.

Construction Sites: Efficiently handles high-capacity tasks.

Food Packaging: Ensures consistent performance in continuous operation scenarios.

Frequently Asked Questions (FAQ)

Scroll compressors are ideal for environments requiring quiet, efficient, and compact solutions, such as medical facilities and residential setups.

It depends on your needs. Scroll compressors are economical for low to medium capacity applications, while Rotary compressors excel in high-demand, continuous-use scenarios.

Scroll compressors require periodic maintenance, such as checking and cleaning filters, to ensure optimal performance. However, their simple design means less frequent maintenance compared to other compressors.

Screw compressors are best suited for industries with high and continuous air demand, such as automotive manufacturing, food processing, and construction.

Yes, both scroll and rotary compressors are available with energy-efficient models. For example, variable speed drive (VSD) technology can reduce energy consumption by adjusting motor speed to match air demand.

Discover RUEGO’s Advanced Air Compressors

Air compressors are essential tools across various industries, each with unique requirements. Whether you’re seeking a compact, quiet solution or a high-performance system for industrial-scale operations, RUEGO has the perfect product for your needs.

Explore Our Scroll Air Compressors

Our Scroll Air Compressors offer:

- Quiet Operation: Ideal for medical facilities, laboratories, and other noise-sensitive environments.

- Compact Design: Saves space without compromising on performance.

- Energy Efficiency: Designed to minimize energy consumption, making them cost-effective for residential and small-scale manufacturing applications.

Visit our Scroll Air Compressor page to learn more about how our scroll compressors can meet your needs.

Discover the Power of Screw Air Compressors

For demanding applications, our Rotary Screw Air Compressors provide:

- Continuous Operation: Perfect for industrial environments such as manufacturing and construction sites.

- High Efficiency: Delivers reliable performance under heavy workloads.

- Durability and Reliability: Engineered to withstand extreme operating conditions.

Learn more about our reliable and efficient screw compressors on our Rotary Screw Air Compressor page.

Why Choose RUEGO?

Our experienced team is dedicated to providing expert guidance from selection to installation and maintenance. We ensure you receive a solution tailored to your specific needs, backed by ISO-certified quality and unmatched reliability.

Contact Us Today

Need help finding the right air compressor for your project? Our specialists are here to assist you. Contact us for more details or a personalized consultation.